From manufacturing lines to automated inspection stations, Watec’s miniature cameras deliver the precision and reliability required for today’s industrial and machine vision challenges. Equipped with ultra-sensitive sensors and using Watec’s ultra low-light patented technology Watec has redefined quality in compact form factors. Watec cameras excel in displaying clear crisp imagery in low light environments where speed, accuracy, and space constraints are paramount.

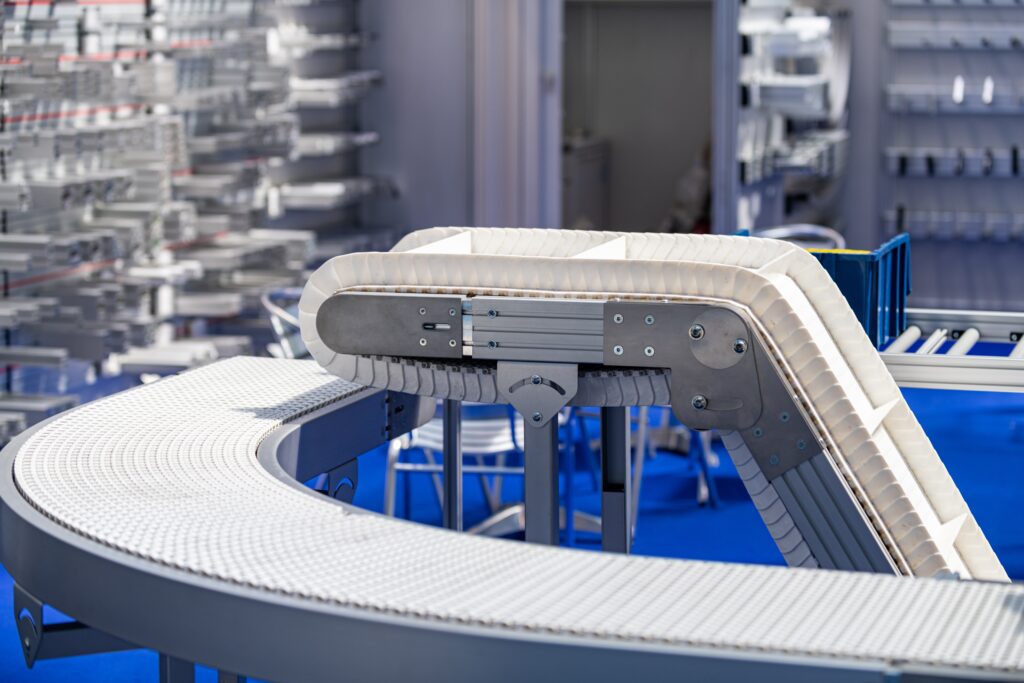

Conveyor Belt Monitoring & Fault Detection

Continuous, real-time monitoring of conveyor belts is critical to avoid costly downtime and ensure worker safety. Machine vision algorithms combined with high-resolution imaging enable early detection of deviance, wear, and damage.

Watec’s compact cameras seamlessly integrate above or alongside belts, feeding clear, high-contrast images into these AI-driven pipelines to prevent malfunctions before they halt production.

Factory Automation & Robotics

Automated assembly lines rely on rapid, precise visual feedback. Watec cameras provide:

- Adjustable Shutter Speeds for motion tracking of parts and components

- Miniature size to fit within robotic end-effectors and tight cell layouts

- Full HD in .0001LUX

According to a 2024 industry report, machine vision adoption in factory automation is projected to grow at a 12% CAGR through 2028, driven by demand for zero-defect manufacturing processes (nature.com).

Watec’s USB and IP-enabled models plug directly into industrial PCs, making deployment straightforward in assembly, pick-and-place, and quality-assurance stations.

Welding Inspection & Quality Control

In welding operations, consistent seam quality is vital. Machine vision systems coupled with high-resolution and ultra low light imaging cameras reduce human error and improve defect detection.

- Studies show integrating cameras into welding stations can cut inspection time by 50% and increase defect catch rates by 35% compared to manual methods.

Watec’s low-light sensitivity and wide dynamic range capability, secured in a durable housing, allow cameras to operate reliably amidst sparks and intense lighting, capturing critical weld details for live feedback and archival records.

Automated Object Recognition

From count-and-sort applications to defect classification, object recognition powered by convolutional neural networks is revolutionizing throughput.

Watec’s compact cameras and lens combinations, integrated with high-resolution sensors deliver the image quality these networks require, even under flickering fluorescent lights and in confined inspection chambers.

Empower Your Industrial Vision Systems

Watec’s full lineup of miniature cameras—designed for harsh factory floors, precision labs, and rugged mining sites—powers the next generation of machine vision. Engineered for reliability, clarity, and ease of integration, our solutions help you:

- Minimize downtime with early fault detection

- Boost yield through precise quality checks

- Optimize layouts by fitting cameras into the tightest spots

Experience industrial imaging redefined. Visit our Amazon store to explore camera kits and vision bundles tailored for your automation needs.